Annex 1 emphasizes the need for a Contamination Control Strategy (CCS), and the Environmental Monitoring System (EMS) forms the feedback loop that indicates the effectiveness of this CCS for controlled areas (cleanrooms and clean enclosures).

The EMS must effectively monitor and minimize contamination using a risk-based approach and by justifying the program’s adequacy. Particular emphasis must be placed on trend analysis and continuous improvement.

Given the ongoing collection of massive amounts of data, an EMS capable of providing information and early warnings is essential.

In most industrial sites, teams are familiar with EMS, but most systems are under-equipped to meet current Good Manufacturing Practice (GMP) requirements.

Where data is not centralised, teams waste time searching for and diagnosing information, or fail to detect deviations early enough, leaving sites exposed to non-compliance during audits and high remediation costs.

This fragmented monitoring imposes a reactive culture rather than a preventive approach to quality.

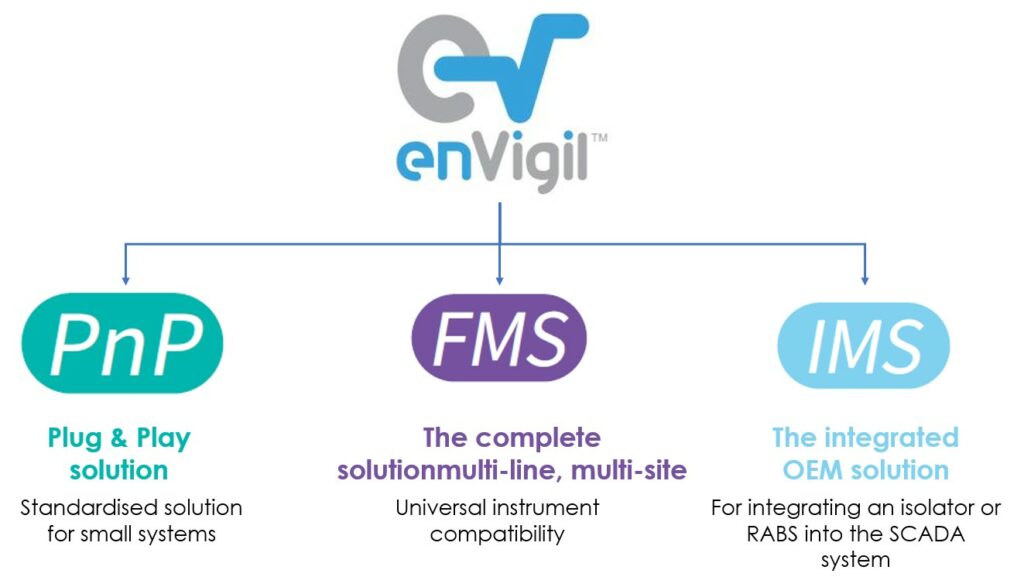

SYNEXIN can help you implement the enVigil solution from its partner Pharmagraph, an EMS that adapts to all operating systems, provides real-time control and visibility with validation at each monitoring stage, and evolves as your needs change.

Thanks to its partner, Pharmagraph, SYNEXIN offers you the enVigil solution:

Discover the benefits of this solution :

| Features : | Benefits : |

| Continuous multi-parameter monitoring | > Full traceability |

| Intelligent alarms | > Early detection of deviations |

| TrendMetrics®: trend analysis | > Data-driven improvement |

| Modular, scalable architecture | > Adapts to your site |

| Redundant design | > Data integrity and availability |

The enVigil solution is compliant from the outset :

Provides real-time control and visibility :

Provides validation and support throughout the lifecycle :

Whatever your needs, we have a solution to meet them… and it’s easy to adapt to changes in your processes !